Exploring the Versatility and Applications of Metal Sheets

Posted on 23 August, 2023 by VIRAAT INDUSTRIES

Metal sheets are essential materials used across industries and applications, renowned for their durability and flexibility. In this comprehensive guide, we'll delve into the world of metal sheets, discussing their types, properties, manufacturing processes, and the diverse range of industries that benefit from their use.

1. Types of Metal Sheets

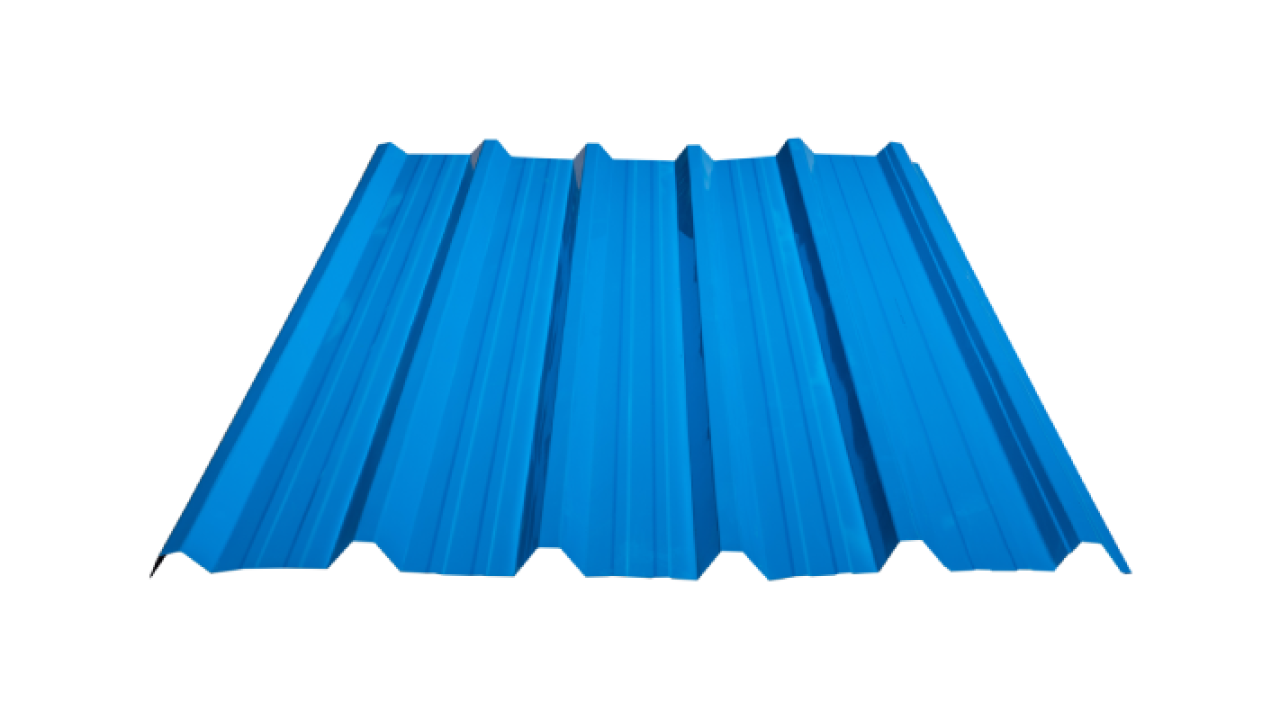

Metal sheet color come in various types, each with distinct properties and applications. Common options include stainless steel sheets for corrosion resistance, aluminum sheets for lightweight durability, and galvanized steel sheets for added protection against rust. Understanding the characteristics of different metal sheets helps you choose the right one for your project.

2. Properties and Advantages

Metal sheets offer a range of advantageous properties. They are known for their strength, malleability, and thermal conductivity. Metal sheets can be fabricated into various shapes and sizes, making them suitable for everything from construction to automotive manufacturing. Their resistance to harsh conditions, coupled with proper coatings, enhances their longevity.

3. Manufacturing Processes

The production of metal sheets involves processes such as rolling, where metal is compressed between rollers to achieve the desired thickness. Cold rolling enhances surface finish and precision, while hot rolling ensures better ductility. These processes result in sheets with consistent thickness and surface characteristics.

4. Industrial Applications

Metal sheets find applications in an array of industries. In construction, they are used for roofing, siding, and structural components. The automotive sector relies on metal sheets for body panels and chassis parts. Additionally, they play a crucial role in manufacturing machinery, appliances, and electronics.

5. Customization and Fabrication

Metal sheets can be tailored to specific requirements through cutting, bending, and welding. Custom fabrication allows for the creation of intricate designs and precise shapes, making them versatile for various projects and applications.

6. Considerations and Maintenance

Selecting the appropriate metal sheet involves evaluating factors like corrosion resistance, strength, and cost. Proper maintenance, such as regular cleaning and protective coatings, ensures the longevity and optimal performance of metal sheets.

Conclusion

Metal sheets stand as indispensable materials in numerous industries due to their versatility, durability, and adaptability. By understanding the types, properties, and applications of metal sheets, you can make informed choices and leverage their benefits across various projects, from construction to manufacturing and beyond.

For more info. visit us:

Second hand roofing sheets for sale in coimbatore