Innovative Manufacturing: Overmolding Services Redefine Possibilities

Posted on 27 July, 2023 by 키즈캠핑장

Innovation in manufacturing techniques has led to the development of various advanced processes that enhance product quality, durability, and functionality. One such remarkable advancement is the utilization of overmolding in the manufacturing industry. overmolding services offer an array of possibilities for product designers, allowing them to create products that were once thought to be impractical or impossible to produce. This article explores the concept of overmolding, its benefits, applications, challenges, and future trends, showcasing how it has redefined possibilities in the world of manufacturing.

What is Overmolding?

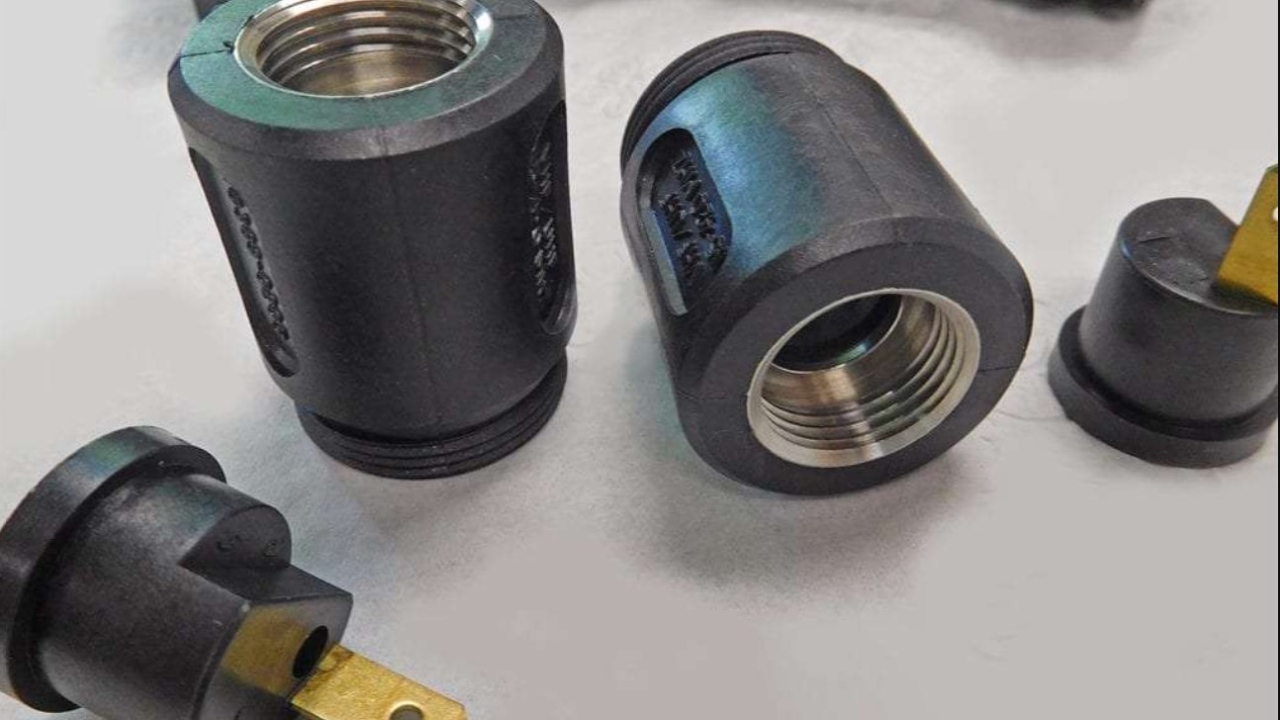

Overmolding is a specialized manufacturing process where two or more materials are combined to create a single, unified product. It involves molding a base or substrate material, typically a rigid component, and then adding one or more additional materials, usually elastomers or thermoplastics, over the base. The result is a final product that boasts the best attributes of each material, making it more durable, comfortable to use, and aesthetically appealing.

The Overmolding Process

The overmolding process involves several crucial steps to ensure a successful outcome. First, the base material is carefully selected, considering factors such as compatibility with the overmold material, structural integrity, and intended application. Once the base is prepared, it undergoes an injection molding process to form the primary shape.

Next comes the overmolding stage, where the second material is injected onto or around the base. The overmold material bonds seamlessly with the base, creating a strong and resilient bond. This process is carried out using advanced machinery, precision molds, and strict quality control measures.

Benefits of Overmolding

Overmolding offers a myriad of advantages that make it a preferred choice for many manufacturers:

1. Enhanced Product Durability

By combining different materials, overmolding creates products that can withstand harsh environments, resist impact, and endure long-term use without degradation.

2. Improved Ergonomics and Aesthetics

Overmolding allows for the incorporation of soft, comfortable materials, making the product easier to handle and enhancing its visual appeal.

3. Cost-Effective Manufacturing

Despite the advanced technology involved, overmolding can streamline the manufacturing process, reducing assembly and production costs.

4. Versatility in Design

Manufacturers can achieve intricate and complex designs with overmolding, giving them the freedom to innovate and differentiate their products.

5. Reduced Noise and Vibration

The combination of materials in overmolding can dampen noise and vibration, leading to quieter and smoother product operation.

Applications of Overmolding in Various Industries

Overmolding's versatility makes it suitable for a wide range of industries:

1. Consumer Electronics

Overmolding is widely used in electronic devices, providing better grip, impact resistance, and protection against environmental elements.

2. Automotive

In the automotive industry, overmolding is utilized for creating comfortable and durable interior components, improving safety and aesthetics.

3. Medical Devices

Medical equipment often employs overmolding to enhance user comfort, ergonomics, and infection control.

4. Household Appliances

Overmolding in household appliances ensures a pleasant tactile experience, improved functionality, and overall longevity.

5. Sports and Leisure

In sports equipment and leisure products, overmolding offers excellent grip, shock absorption, and weather resistance.

Advancements in Overmolding Technology

The continuous advancements in overmolding technology have opened up new possibilities:

1. Multi-Shot Overmolding

Multi-shot overmolding allows the combination of more than two materials, offering greater flexibility in product design.

2. Insert Molding

Insert molding integrates pre-fabricated components, such as metal inserts, into the overmolded part during the molding process.

3. 3D Printing and Overmolding

The integration of 3D printing technology with overmolding has revolutionized the production of custom and personalized products.

4. Smart Materials

Researchers are exploring the use of smart materials that respond to external stimuli in overmolding applications, enabling dynamic product behavior.

Key Considerations for Choosing an Overmolding Service Provider

Selecting the right overmolding service provider is essential for a successful project:

1. Expertise and Experience

Look for a service provider with a proven track record in overmolding and experience in your specific industry.

2. Material Selection Guidance

A reliable provider will offer guidance in choosing the right materials for your project, ensuring optimal performance.

3. Design and Prototyping Support

Ensure the service provider offers design assistance and prototyping services to fine-tune your product concept.

4. Quality Assurance

Quality control measures and certifications are crucial indicators of a reputable overmolding service provider.

5. Timely Delivery

Choose a provider that can meet your project timeline without compromising on quality.

Overcoming Challenges in Overmolding

Despite its advantages, overmolding comes with its share of challenges:

1. Material Compatibility

Ensuring compatibility between the base and overmold materials is critical to prevent delamination and product failure.

2. Tooling Complexity

Overmolding requires intricate molds, which can increase initial tooling costs.

3. Dimensional Accuracy

Maintaining precise dimensions during the overmolding process is vital to avoid defects and inconsistencies.

4. Production Scalability

Scaling up production while maintaining product quality demands careful planning and execution.

Sustainability and Overmolding

The manufacturing industry's increasing focus on sustainability has influenced overmolding practices:

1. Eco-Friendly Materials

Manufacturers are exploring bio-based and recyclable materials for overmolding to reduce environmental impact.

2. Energy Efficiency

Optimizing the overmolding process to conserve energy and minimize waste contributes to sustainability goals.

Future Trends in Overmolding

The future of overmolding holds exciting possibilities:

1. Miniaturization

Advancements in micro-molding techniques will enable overmolding of smaller and more intricate components.

2. IoT Integration

Overmolding will play a crucial role in integrating sensors and electronics for the Internet of Things (IoT) devices.

3. Enhanced Material Combinations

Researchers will continue to explore innovative material combinations to push the boundaries of overmolding applications.

4. Additive Manufacturing Integration

Combining overmolding with additive manufacturing will offer unmatched design flexibility and customization.

Overmolding vs. Other Manufacturing Techniques

Comparing overmolding with traditional manufacturing methods:

1. Overmolding vs. Two-Shot Molding

Unlike two-shot molding, which uses two different materials in separate shots, overmolding combines materials in a single step.

2. Overmolding vs. Insert Molding

Insert molding integrates pre-fabricated components, while overmolding covers the base entirely with the second material.

3. Overmolding vs. Co-Injection Molding

Co-injection molding involves injecting two materials simultaneously, while overmolding uses a sequential process.

Case Studies: Successful Implementations of Overmolding

Several success stories highlight the potential of overmolding:

1. Improved Grip in Power Tools

A power tool manufacturer implemented overmolding to enhance the grip on their products, resulting in increased user satisfaction.

2. Customizable Earbuds

A consumer electronics company used overmolding to create customizable and comfortable earbuds, attracting a broader customer base.

3. Automotive Interior Innovation

An automotive company overmolded soft-touch materials onto interior components, creating a luxurious feel for their vehicles.

How to Get Started with Overmolding for Your Product

Follow these steps to initiate an overmolding project:

1. Identify the Need

Determine if overmolding can improve the functionality, aesthetics, or durability of your product.

2. Partner with Experts

Collaborate with an experienced overmolding service provider to bring your concept to life.

3. Material Selection

Select the appropriate materials based on the intended application and desired characteristics.

4. Prototype and Test

Create prototypes to validate your design and conduct rigorous testing to ensure performance and quality.

5. Scale-Up Production

Once the prototype meets expectations, scale up production to meet market demands.

Conclusion

Overmolding services have undeniably redefined possibilities in the manufacturing industry. By combining materials, manufacturers can create products that excel in performance, ergonomics, and aesthetics. From consumer electronics to automotive components, the applications of overmolding are vast and diverse. As technology continues to evolve, the future holds even more exciting innovations in the world of overmolding, bringing forth a new era of advanced and sustainable manufacturing.

FAQs

-

What is overmolding? Overmolding is a manufacturing process that involves combining two or more materials to create a single product, offering enhanced durability and aesthetics.

-

What industries benefit from overmolding? Industries such as consumer electronics, automotive, medical devices, household appliances, and sports equipment can greatly benefit from overmolding.

-

How can I choose the right overmolding service provider? Consider their expertise, material selection guidance, design support, quality assurance, and timely delivery when selecting an overmolding service provider.

-

What challenges does overmolding present? Overmolding may face challenges related to material compatibility, tooling complexity, dimensional accuracy, and production scalability.

-

What does the future hold for overmolding? The future of overmolding looks promising with trends like miniaturization, IoT integration, enhanced material combinations, and additive manufacturing integration on the horizon.

https://vjclinics.com/

12 August, 2019

http://botoxandfillerspune.com/

12 February, 2019