Procurement Resource Analyses the Production Cost of Styrene Acrylonitrile Resin in its New Report

Posted on 28 July, 2022 by Jolie Alexa

Procurement Resource Analyses the Production Cost of Styrene Acrylonitrile Resin in its New Report

Analyses Overview of The New Production Cost Report of Styrene Acrylonitrile Resin

The new report by Procurement Resource, a global procurement research, and consulting firm, looks in-depth into the costs involved in the production of Styrene Acrylonitrile Resin. The comprehensive report analyses the production cost of the material, covering the raw material costs and co-product credit, equipment costs, land and site costs, labour wages, maintenance costs, financing charges, and depreciation costs. The extensive study describes the stepwise consumption of material and utilities along with a detailed process flow diagram. The report also assesses the latest developments within the industry that might influence Styrene Acrylonitrile Resin production cost, looking into the capacity expansions, plant turnarounds, mergers, acquisitions, and investments.

Product Definition:

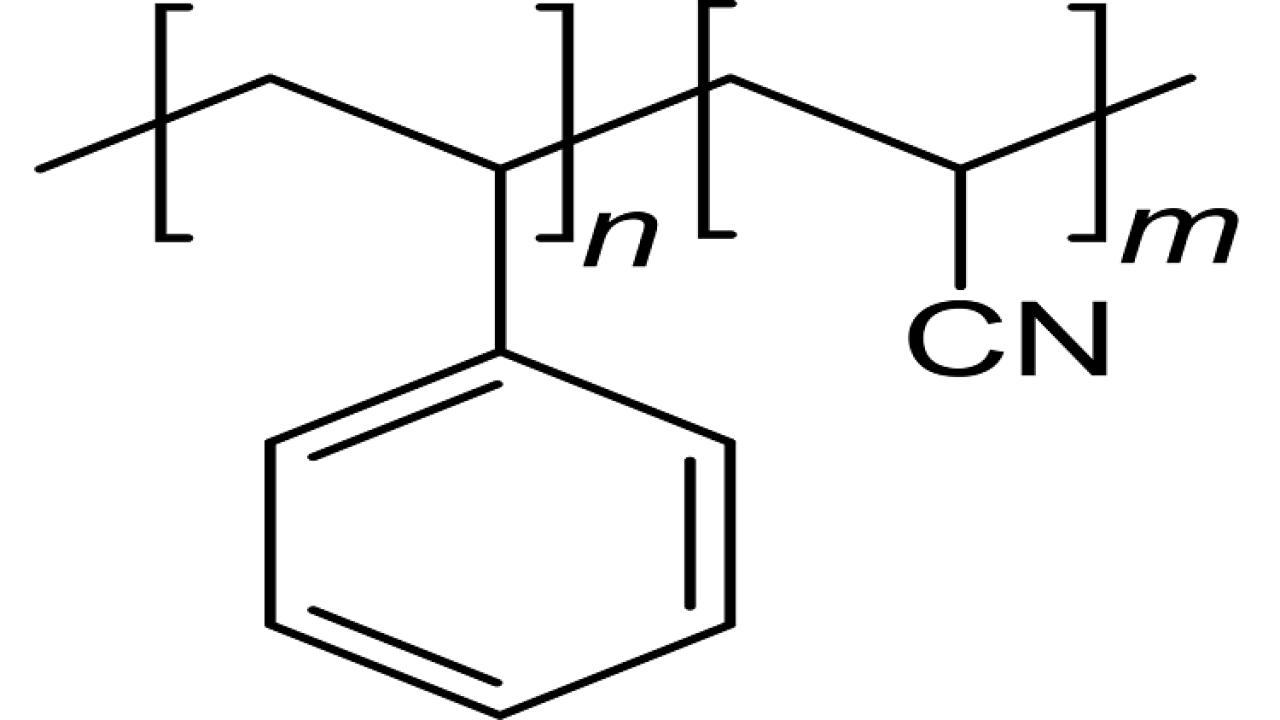

Because of the features etched with styrene-acrylonitrile resins such as chemical resistance, immense stiffness, extended heat resistance, processability, and so on, the styrene-acrylonitrile resins market is expected to develop significantly between 2020 and 2030.

Factors Impacting the Styrene Acrylonitrile Resin Production Cost:

Throughout the assessment period, the widespread usage of styrene-acrylonitrile resins in a range of applications in end-users such as automotive, building and construction, packaging, construction, and others may provide significant potential prospects for the styrene-acrylonitrile resins market. The styrene-acrylonitrile resins market is divided into two categories based on product: preliminary working styrene-acrylonitrile resins and secondary styrene-acrylonitrile resins. These factors are expected to impact the production cost of Styrene Acrylonitrile Resin.

Procurement Resource Assessment of Styrene Acrylonitrile Resin Production:

The cost of producing Styrene/Acrylonitrile (SAN) copolymers from styrene and acrylonitrile in bulk polymerization is examined in this report. In the presence of ethylbenzene, continuous mass copolymerization of acrylonitrile and styrene to styrene-acrylonitrile resin occurs. The reaction result is devolatilized, which allows the monomers to be recovered and recycled. To make styrene-acrylonitrile resin, the SAN melt goes through an extrusion and pelletizing machinery.

About Us:

Procurement Resource ensures that our clients remain at the vanguard of their industries by providing actionable procurement intelligence with the help of our expert analysts, researchers, and domain experts. Our team of highly seasoned analysts undertake extensive research to provide our customers with the latest and up-to-date market reports, cost-models, price analysis, benchmarking, and category insights, which aid in simplifying the procurement process for our clientele. We work with a diverse range of procurement teams across industries to get real-time data and insights that can be effectively implemented by our customers. We also track the prices and production costs of an extensive range of goods and commodities, thus, providing you with the updated and reliable data. We, at Procurement Resource, with the help of the latest and cutting-edge techniques in the industry, help our clients understand the supply chain, procurement, and industry climate, so that they can form strategies which ensure their optimum growth.

Contact Us:

Company Name: Claight Corporation

Contact Person: Jolie Alexa

Email: [email protected]

Toll Free Number: USA & Canada: +1-415-325-5166 | Europe & Africa: +44-702-402-5790 | APAC: +91-8586081494

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Blog - https://procurementresource.blogspot.com/

Website: https://www.procurementresource.com/

Reference Link: https://takeitcool.com/production-cost-of-styrene-acrylonitrile-resin/

http://tgifindia.com

3 January, 2017