Procurement Resource Analyses the Production Cost of Cyclohexane in its New Report

Posted on 7 July, 2022 by Jolie Alexa

Procurement Resource Analyses the Production Cost of Cyclohexane in its New Report

Analyses Overview of The New Production Cost Report of Cyclohexane

The new report by Procurement Resource, a global procurement research, and consulting firm, looks in-depth into the costs involved in the production of Cyclohexane. The comprehensive report analyses the production cost of the material, covering the raw material costs and co-product credit, equipment costs, land and site costs, labor wages, maintenance costs, financing charges, and depreciation costs. The extensive study describes the stepwise consumption of material and utilities along with a detailed process flow diagram. The report also assesses the latest developments within the industry that might influence Cyclohexane production cost, looking into the capacity expansions, plant turnarounds, mergers, acquisitions, and investments.

Product Definition:

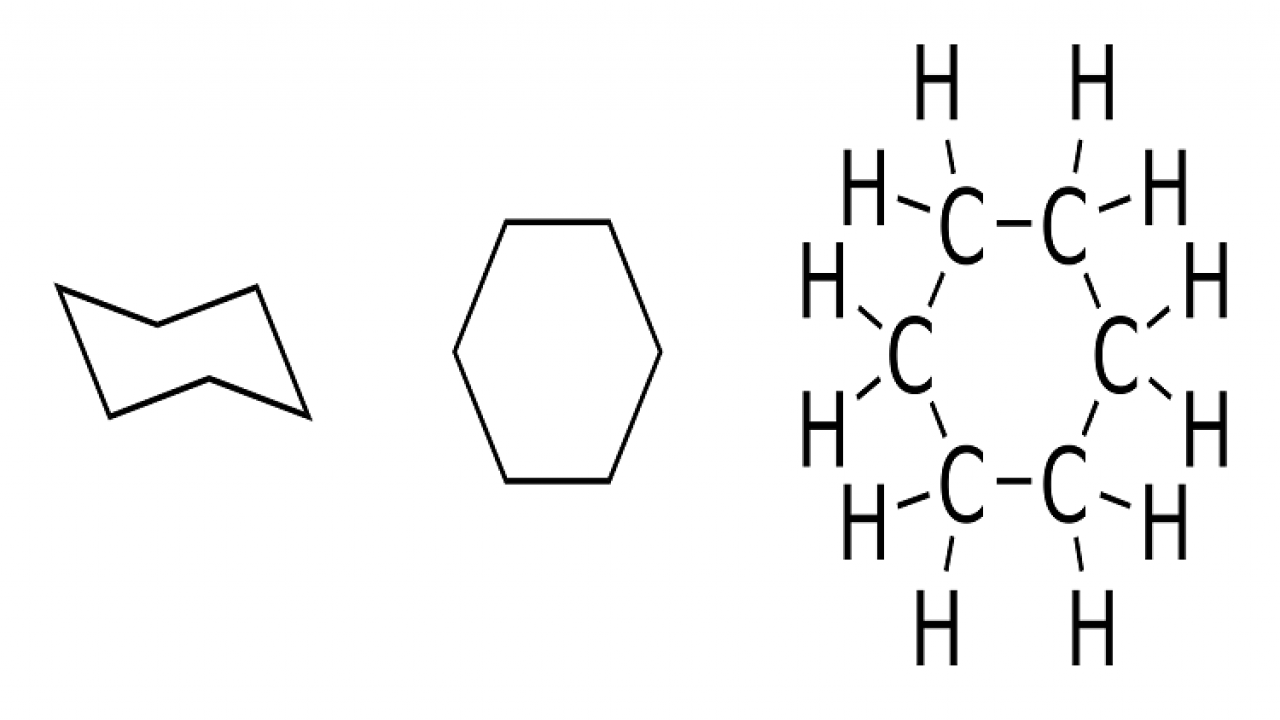

Cyclohexane is a colourless cycloalkane with a pleasant, gasoline-like odor. Cyclohexane is most commonly used in the synthesis of adipic acid and caprolactam, both of which are precursors to nylon. Nylon is commonly used to make carpets, upholstery, furniture, floor coverings, and conveyor belts. In ether, alcohol, and acetone, cyclohexane dissolves well.

Factors Impacting the Cyclohexane Production Cost:

Adipic acid, hexamethylene diamine, and caprolactam are all made from cyclohexane, which is then used to make Nylon 6,6 and Nylon 6. Nylon 6 is made via caprolactam polymerization, whereas Nylon 6,6 is made from adipic acid and hexamethylenediamine polymerization. Carpets, upholstery, furniture, and floor coverings, typewriter ribbons, nylon ropes, and cordages, fishing nets, strimmer lines, umbrella fabric, sutures, conveyor belts, and other applications are just a few of the many uses for nylon. The market for goods is projected to be driven by the increasing usage of Nylon.

Procurement Resource Assessment of Cyclohexane Production:

The production cost report by Procurement Resource assesses the production of Cyclohexane production from Benzene. Cyclohexane is made from Benzene and Hydrogen in this procedure. The method used is benzene hydrogenation in the liquid phase. In the presence of nickel as a catalyst, the reaction proceeds. In the main reactor, benzene releases all its bonds and adds hydrogen to them.

About Us:

Procurement Resource ensures that our clients remain at the vanguard of their industries by providing actionable procurement intelligence with the help of our expert analysts, researchers, and domain experts. Our team of highly seasoned analysts undertake extensive research to provide our customers with the latest and up-to-date market reports, cost-models, price analysis, benchmarking, and category insights, which aid in simplifying the procurement process for our clientele. We work with a diverse range of procurement teams across industries to get real-time data and insights that can be effectively implemented by our customers. We also track the prices and production costs of an extensive range of goods and commodities, thus, providing you with the updated and reliable data. We, at Procurement Resource, with the help of the latest and cutting-edge techniques in the industry, help our clients understand the supply chain, procurement, and industry climate, so that they can form strategies which ensure their optimum growth.

Contact Us:

Company Name: Claight Corporation

Contact Person: Jolie Alexa

Email: [email protected]

Toll Free Number: USA & Canada: +1-415-325-5166 | Europe & Africa: +44-702-402-5790 | APAC: +91-8586081494

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Blog - https://procurementresource.blogspot.com/

Website: https://www.procurementresource.com/

Reference Link: https://takeitcool.com/production-cost-of-cyclohexane/